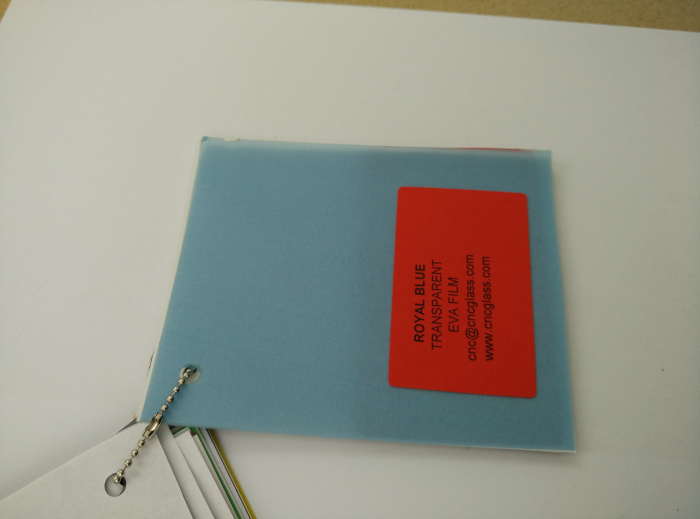

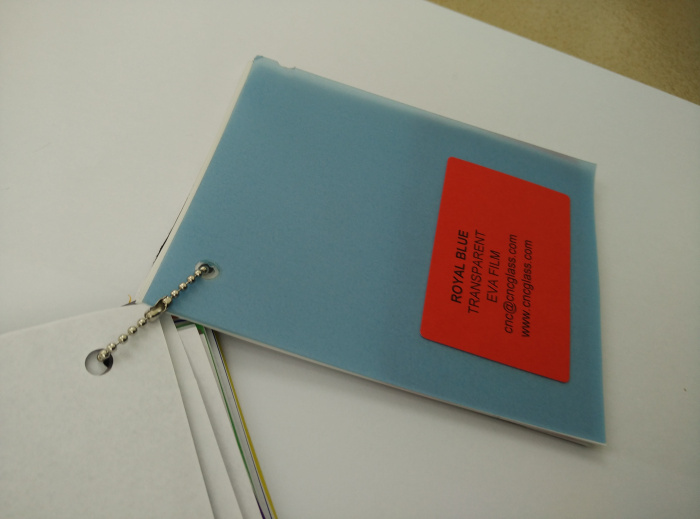

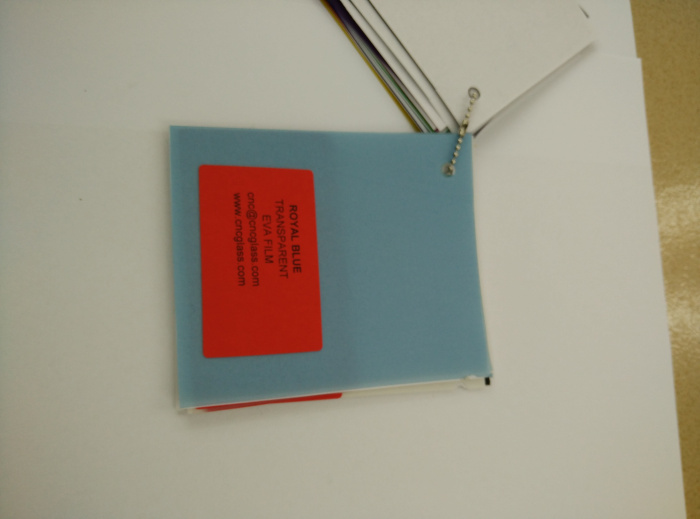

Royal Blue Ethylene Vinyl Acetate Copolymer EVA interlayer film for laminated glass safety glazing

Wet Liquid Safety Glazing Methods for manufacturering laminated glass

Cast in place (CIP)

The edges of the glasses are taped using translucent double-sided adhesive tape. The tape retains the liquid and determines the thickness of the resin interlayer. The liquid resin is pumped, into the envelope, where it spreads evenly – even between irregular surfaces. All the air is removed out and corners and drilled holes are sealed with a translucent silicone to prevent the resin from escaping. The glass is put beneath UV lamps for approximately 20 minutes. CIP is ideal for curved and domed glass, where exceptional optical quality is required.

Ethylene vinyl acetate (EVA) for laminated glass safety galzing

Ethylene vinyl acetate (EVA)

A sheet film of EVA (to a maximum width of 2.3 meters) is placed between two sheets of glass, a vacuum is applied to force the glasses together and suck out air to avoid bubbles, and then it is heated to soften the film and make it adhere to the glass.

EVA has a high tensile strength, excellent transparency, outstanding cohesion properties, good resilience to temperature changes, humidity, durability and long-term reliability. It is ideal for areas prone to moisture such as shower screens and wet rooms. It is often used for increased safety, security and sound insulation for various indoor and outdoor applications.

Laminated safety glass is considerably more impact resistant than conventional glass. Tests have shown it is some 30 times more intruder-resistant than conventional toughened glass. It is strong enough to withstand a vigorous attack from a heavy or sharp weapon. It can resist an aggressive attack for 20 to 30 seconds compared to toughened glass which would resist a similar attack for only one or two seconds.

PET GREEN TAPE, EVAFORCE FILM SAMPLES, EVA THERMAL CUTTER

Comparing Tensile Strength of CNC Glass Interlayer EVA Film: EVAFORCE EXTREME

Written by Peter Lin

Tensile Strength Test of Super Clear EVA Film Samples of an international famous supplier

1-Tester: Peter Lin

2-Test Time: May, 26, 2014.

3-EVA Film Samples: Super Clear EVA Film Samples of an international famous supplier

4-Speed: 300mm/min

5-Laminating Time and Temperature: 85°-15′130°-40′

No. Max

(N) Tensile Strength

(MPa) Elongation

(%) Young’s modulus

(MPa)

1 78.934 18.794 633.768 1.337

2 62.488 15.622 664.459 1.060

3 69.637 16.580 639.186 1.207

4 55.525 13.543 584.743 0.991

5 64.980 15.471 610.706 1.124

6 65.921 16.078 610.949 1.177

7 62.449 14.193 607.018 1.001

8 61.194 14.570 622.803 1.014

9 55.506 13.538 592.248 0.983

Max. 78.934 18.794 664.459 1.337

Min. 55.506 13.538 584.743 0.983

Average 64.070 15.377 618.431 1.099

Tensile Strength Test of CNC Glass Interlayer EVA Film: EVAFORCE EXTREME

1-Tester: Peter Lin

2-Test Time: May, 26, 2014.

3-EVA Film Samples: EVAFORCE EXTREME of CNC Glass Interlayer

4-Speed: 300mm/min

5-Laminating Time and Temperature: 85°-15′130°-40′

No. Max

(N) Tensile Strength

(MPa) Elongation

(%) Young’s modulus

(MPa)

1 78.895 19.243 528.706 1.553

2 66.264 16.162 519.201 1.337

3 85.044 21.261 554.858 1.630

4 71.030 17.324 534.723 1.371

5 68.706 16.757 533.400 1.324

6 66.205 16.148 482.024 1.464

7 76.561 18.673 543.838 1.457

8 68.382 16.281 484.427 1.471

9 89.015 21.711 565.189 1.642

Max. 89.015 21.711 565.189 1.642

Min. 66.205 16.148 482.024 1.324

Average 74.456 18.173 527.374 1.472

Conclusion:

EVAFORCE EXTREME of CNC Glass Interlayer performs better tensile strength and Young’s modulus than the international famous supplier’s Super Clear EVA Film samples.

EVAFORCE EXTREME super clear EVA interlayer film is the first world-class level .interlayer for safety laminated glass.

EVA FILM

EVAFORCE® EXTREME

*Super Clear

*For Architectural Safety Laminated Glass

*Less Overflow When Heating

*Strengthened Mechanical Properties

*Recommended For Extreme Environments

*Best Choice For Curved Glass Laminating

*Applied Both Indoor And Outdoor

*Replacing PVB Film

Make Switchable Smart Glass in Laminating Oven Method

How to Make Smart GLass with Non-Adhesive Smart Film in Laminating Way

Make Switchable Smart Glass in Laminating Oven Method

By Peter Lin www.cncnext.com www.helloglass.com

+The Composition of Smart Glass (Switchable Glass, Privacy Glass, Magic Glass )

-Two outside layers of float glass

-Two layers of laminating adhesive film inside the glasses, can be Ethylene-vinyl acetate EVA Interlayer Film or Polyvinyl Butyric PVB Interlayer Film

-Magic Smart Film, also named as PDLC FILM (Polymer dispersed liquid crystal devices) in the center

-GLASS

-EVA FILM

-SMART FILM

-EVA FILM

-GLASS

+Clean the flat glass

+Clean the Switchable Smart Film

+Combine the Float glass, EVA film, Smart FILM, EVA FILM, Float Glass to be a whole Pre-Laminated Smart Glass

–Glass

–EVA Interlayer film

–Switchable Smart Film

–EVA Interlayer film

–Glass

+Use tape to fix the pre-laminating smart glass

+Put the pre-laminating smart glass into the silicone vacuum bag

+Start to heat the pre-laminating smart glass

+Finish heating, take the smart glass out of silicone vacuum bag

+Join the bus bar and the wire

+Assembling insulating protector and the switchable smart glass is finished.

All rights reserved by CNC-INTERLAYER TECH:

CNC-Smart® SMART FILM FOR PRIVACY SWITCHABLE GLASS

Web: www.CNCnext.com

Mail: [email protected]

[email protected]/ [email protected]

Silicone Bag for Laminated Glass Machine Laminating EVA Interlayer Film

Silicone Bag for Laminated Glass Machine Laminating EVA Interlayer Film

www.Ucolin.com

+EVA Film:

EVA stands for ethylene vinyl acetate, a copolymer resin used in the production of laminated glass as the interlayer sandwiched between two pieces of glass. The main function of the interlayer is to stick the two piece of glass together, in order to make the sandwiched glass safer and more secure.

EVA Film is made out of macromolecule material and it performs excellent in bonding strength, heat resistance, cold resistance, humidity resistance and tensile strength in laminated glass. It has been partly taking the places of PVB film in laminated safety glass, laminated art glass, laminated color glass.

EVA film is not adhesive before heating. After heating, it melts and reacts. In the production of laminated glass with EVA interlayer, no autoclave, roller press, air bag, or vacuum rubber ring is required. As EVA interlayer can be processed under normal climatic conditions, no clean room with climatic control is required. And the producing machine of laminated glass with EVA Film is less cost and easier to process.

+Laminated Glass with EVA Film

Laminated Glass with EVA Film is an important kind of laminated glass in glass industry .The processing principle of EVA laminated glass is similar to most of the laminated glass . Furthermore, using EVA film to laminating glass does not require autoclave. All laminating processing will be finished and completed in one vacuum laminator. EVA Film for laminated glass has excellent transparency, outstanding adhesion and aging-resistance (more than 15 years), can be used for architectural glass, decorative glass with fabric, privacy glass, auto glass etc.

+EVA Vacuum Glass Laminating Machine is a equipment specially designed for manufacturing laminated safety and decoration glass with Ethylene-vinyl acetate EVA Interlayer Film (some kind of the one-step glass laminating machine can also processing Polyvinyl Butyral PVB Interlayer Film).

The EVA Vacuum Glass Laminating Machine uses the silicone vacuum bag to make the pre-laminated glass is heating in the vacuum condition to guarantee that final laminated glass don’t have bubbles.

It’s also possible to laminate EVA Interlayer Film with silk, paper, calligraphy and painting, ultraviolet radiation unilateralism film, light adjusted film and so on. All kinds of art glass, decorated glass, privacy glass, safety glass and solar panel can be processed in the EVA Vacuum Glass Laminating Machine.

Compared to autoclave producing line for Polyvinyl Butyral PVB Interlayer Film, the EVA Vacuum Glass Laminating Machine is much easier to operate and less cost to build., and more flexible and convenient for the designer.

+Silicone Bag for Laminated Glass Machine Laminating EVA Interlayer

+Product features:

Great heat-resistant,

Great aging-resistance ,

Great resistance to EVA

Anti-corrosive,

Environment-friendly,

Long-use life,

+Product specification:

1) Common thickness: 3mm

2) Maximum width:3800mm without any joints

3) Any length

4) Common color: Milky (other color is available for custom)

5) Custom as customers require

All Rights Reserved By UCOLIN SILICONE TECH

(1)-Silicone Vacuuming Bag for EVA Glass Laminating Machine/Privacy Glass Laminating

(2)-Silicone Sheet for EVA Glass Laminating Machine

(3)-Silicone Bag for PVB Glass Laminating Auto-clave

(4)-Silicone Rubber Sheet for Solar Cell Module Laminating Machine

(5)-Contact Us: [email protected] / www.ucolin.com

[email protected]/ [email protected]

CNC REAR PROJECTION FILM

CNC REAR PROJECTION FILM

CNC rear projection films can be easily applied to glass / Plexiglas.

Width 1524mm X Length 30m/roll

Multiple pieces of film can be joined on glass to create large format displays.

=Pro Diffusion Rear Projection Film

Pro Diffusion film is a high contrast rear projection film mainly used for store window displays and high end video applications. This rear projection screen film offers superior brightness, contrast and black levels even in high ambient light and daylight.

Shapes and sizes are also available for customization and pieces can be joined to create large format displays.

Pro Diffusion film has a self adhesive layer (peel and stick) making it easy to apply to any kind of glass or Plexiglas.

=High Gain Rear Projection Film

High Gain rear projection film is a specialist rear projection film primarily used for store window displays and advertising screens. This low cost projection film offers superior brightness in high ambient light and daylight.

What kinds of shapes and sizes are also available for customization and multiple pieces can be joined to create large format displays.

High Gain rear projection film is manufactured with a self adhesive layer meaning it can be easily applied to glass or Plexiglas. High Gain film is a cost effective screen technology which can perform well with lower powered, less expensive projectors.

CNC-Projection Glass Film

Specifications :

Color: Transparent, Gray, Double Gray, White, Double White

Width: 1524mm (60”)

Length: 1 roll = 15 meters (Minimum Order)

Haze: 33%

Thickness: 100μm

UV-Fading Protection % : 0.20%

Visible-Natural Daylight %: 70%

SHGC-Heating &

Cooling cost %: 0.6

Viewing Angle: 165°

Hardness: 3H

CNC-INTERLAYER TECH:

[Product 1]CNC-Force EVA INERLAYER FOR ARCHITECTURAL LAMINATED GLASS

[email protected]

[Product 2]CNC-SmartSMART FILM FOR PRIVACY SWITCHABLE GLASS

[email protected]

[Product 3]CNC-Shield PVB INTERLAYER FOR AUTOMOTIVE WINDSHIELD GLASS

[email protected]

Web: www.CNCglass.com www.CNCnext.com www.HelloGlass.com

Mail: [email protected]

[email protected]/

[email protected]

Beveling Edging Machine Straight-Line Machine Inside and outside the circle Internal and external circular

GLASS MANUFACTURER MAIN PRODUCT

======================================

Product Features:

This machine is a nine-head bevel and bottom grinding machine, it can complete rough grinding and fine grinding in one time, the polished effect is similar to a mirror surface, with accurate ground angles. Control system uses PLC control,automatic,manual conversion.Man-machine interface clearly shows that the glass thickness,width and angle of hypotenuse,and the remaining glass thickness and various parameters,such as proceeing speeds,transmission speed using variable

frequency adjustment.

Chain plates are made of thicker steel plates and the slide gibs are made with a number of special processing techniques with such features as superior abrasion resistance, deformation resistance, and stable operation etc. The motor of the machine has a solid body, high precision, low-power consumption, suitable for beveling and milling processing of large quantities of glass parts.

Main techno logy parameter

ZM9325-45°glass straight edging machine adding multi-level edging function than conventional machine,i.e. edging glass ranging from 45°to 90°degree base line.

WHEEL CONFIGURATION

Main techno logy parameter

The machine is suitable for grinding peripheral edge such as pencil,OG flat edge with arrises,and bevel of different shape glassby equipping different kinds of wheels, It used shaping-grinder to be grinded and polished,and carl grind high-accuracy,high-quality glass.It provided withsteplees speed variator regulating the speed of processing.

Main techno logy parameter

The machine is suitable for grinding two straight-line edges of furniture glass,architecture glass ,and electrical applianceglass and So on ;it has characters of rapid peed ,high brightness .the machine adopts high precision transmission structure with two linear guiding bars and two ball bearing guide screw.It is equipped with PLC system on the electric control part. It fixed superior man-machine interface screen operation system. Grinding head distribution

Main techno logy parameter

ZNWM1320 is applied for processing interior&exterior circular edges,elliptical and uneonventional-shape edging machine with dual modes of manual and pneumatic operations.

ZDYM1320 glass shape edging machine is suitable for processing perimeter and bevel edges of round and oval shaped glass. It uses satellite wheel for rotation, the wheel rotation speed can be adjusted during work. This machine can also be used for semi-auto grinding of simple special shaped glass. When grinding peripheral edges, it can use three grinding wheels for coarse and fine grinding and polishing. When grinding bevel edges, it can use a bowl shaped grinding wheel, the grinding head can be tilted back, and the bevel angle can be adjusted for end face grinding. Main techno logy parameter

The machine is adopted automatic cleaning and dryness for glass and lens in diverse thickness in horizontal thickness in horizontal transmission with 8 brush pole cleaning and 6 sponge absorbing;strong hot wind dryness system.Automatic-controlled temperature and feeding speed.Specifications of ZYX cleaning machine such as:ZYX500、ZYX800、.ZYX1200、ZYX1600、ZYX2500 Main techno logy parameter

Equipped with two motors for driving two sand belts to process glass edges.Manual operation,the arris grinding can be finished swiftly.Suitable for glass doors,widows and the glass before tempering. Main techno logy parameter

GLASS MANUFACTURER PRODUCT LIST

======================================

Beveling Edging Machine Straight-Line Machine Round Edging Machine Inside and outside the circle Internal and external circular Double Edging Machine Washing & Drying machine Abrasive Trimming Sand Spraying Machine Laminating machine Fillet Machine Drilling Machine Cutting Process Line

======================================

GLASS MANUFACTURER CONTACT INFO

======================================

Address: Lunjiao Industrial Road (200 meters to the east of State Highway 105), Shunde District, Foshan City, Guangdong Province

P.C: 528308 QQ:294872678

TEL: +86-757-27335268

FAX: +86-757-27335263 Http: www.zhengyi.cc

www.中国正意.中国

E-mail: [email protected]

GLASS MANUFACTURER COMPANY PROFILE

======================================

Foshan Shunde Zhengyi Glass Machinery Co., Ltd is a manufacturer specialized in producing glass deep processing equipment, with rich experience accumulated in twelven years of production, strong technical force, and excellent processing equipment.

The company is located in the center of the beautiful and rich Pearl River Delta, it is only15 kilometers away from Foshan City, 30 kilometers away from Guangzhou, and its transportation is very convenient.At present, the products of the company include: beveling machine series, straight edge machine series, special shape machine series, cleaning machine series, drilling machine series and other glass deep-processing equipment of all kinds of varieties and specifications, it can also specifically design customized products according to the specific requirements of users: Wide beveling machines, ultra-small glass piece edge milling machines, special shape grinding machines and scalloped edge grinding machines and so on. Its products have good quality and reliable performance.

“developing by technology, Integrity and responsibility.” is the company’s business tenet. All of our products are made under this tenet in each procedure, from design, manufacturing, to services. Users’ need is our motive power; customer satisfaction is the best assessment to us, promoting the development of the industry is the social return of Zhengyi Machinery.

Коли деякі клієнти обробки багатошарове скло з плівкою EVA прошарок,

[email protected] / [email protected]

www.cncnext.com + + Що люди можуть думати, коли вони стикаються з бульбашками

Коли деякі клієнти обробки багатошарове скло з плівкою EVA прошарок,

з’являються бульбашки всередині ламінованого скла, люди завжди будуть

думати таким чином: 1-фільм EVA прошарок я замовив в минулий раз, не було бульбашок

проблема, чому в цей раз бульбашки виходить, що виразно причина якість

фільму прошарок EVA. 2-Деякі клієнти стикаються з цією ситуацією. Може бути, вони не

використовують EVA фільм прошарок дуже багато, тому вони не закінчити

один рулон плівки прошарок EVA протягом короткого періоду. Вони

використовували дві третини з рулону плівки EVA прошарок, і через

декілька тижнів вони повертаються використовувати ліву частину рулону.

Але на цей раз бульбашки виходять, вони дуже збентежений. Чому ж рулон

плівки EVA прошарок має різні якості? 3-Some клієнт може просто змінити новий прошарок EVA фільм

постачальником і бульбашок виходить. Навіть їх новим постачальником

сказати їм, що вся справа в обробці, вони б не повірили йому, вони

думають, що це, звичайно, проблема якості вашої EVA фільм прошарку,

тому що EVA фільм прошарком з моїх старих постачальників не мають

цього міхури проблеми. + + Загальні причини для Bubbles

Багато виробників ламінованого скла мають неправильне уявлення про

причини бульбашок проблем. Ось реальна чому: 1-Перша ситуація: температура занадто висока, може бути, більше, ніж

160 градусів, що призведе до EVA та інші сполуки, щоб зламати і

створити газу. Таким чином, це просто знижуючи температуру, і все буде

в порядку. 2-друга ситуація: температура в печі не середній, який означає, що

деякі частини скла, жаркіше, ніж інші. Таким чином, деякі частини EVA

фільм прошарок розтане і закінчити поперечних зв’язків реакцію в той

час як інші частини фільму EVA прошарок ще не розтанув, який буде

переривати пилососом і викликають бульбашки. У цій ситуації, ми

пропонуємо вам змінив ламінування машини. 3-третьої ситуації: вакуумна машина стара або вакуум здатність не

досить добре. Якщо вакуумна машина стара, продовжити його. Якщо вакуум

здатність не є достатньо потужним, намагайтеся купувати нову. 4-чотири ситуації: вологість повітря висока. Вологу в повітрі у вашому

регіоні змінилася, яке легко викликати EVA фільм прошарок вологої,

коли він надає в повітрі. Волога у відкритий космос фільм прошарку

призведе до того, бульбашки. Хоча фільм EVA прошарок менш чутливий до

вологи в порівнянні з плівкою ПВБ. Але якщо вологи плівки EVA прошарок

надто висока, бульбашки будуть також виходити. Деякі клієнтові відкрити упакований одного рулону плівки EVA прошарок,

і не використовувати його в один час. А ліва частина фільму прошарок

EVA буде вбирати вологу в повітря і викликають бульбашки. 5-п’ять ситуацій: різні прошарки EVA фільм постачальник має іншу

формулу для фільму EVA прошарок, так що якщо ви зміните EVA

постачальником ФІЛЬМ прошарок, необхідно настройці параметрів обробки

відповідно до EVA власності прошарку ФІЛЬМ постачальника. + + Micro Причини Bubbles:

1-невигадливість загартоване скло погано. – Як вам відомо, загартоване скло є менш простим, ніж плоске скло.

Таким чином, ви повинні вибрати компанію, яка виробляє кращі

загартованого скла. – З простотою загартованого скла гірше, ніж листове скло, ви повинні

використовувати товщі прошарок EVA плівки для загартованого скла.

Взагалі кажучи, загартоване скло повинне бути ламіновані, принаймні

0,76 мм товщини прошарку EVA. – Ламінат менше шарів “пре-ламіноване скло” в кремнії сумку за один

раз. Якщо ви ламінату занадто багато шарів “пре-ламіноване скло” в

кремнії сумку в один час, пилососити не буде працювати ідеально і

викликають бульбашки. – Якщо ви ламінованих шматочків “до багатошарових стекол” в той же

час, поставити “до багатошарових стекол” на тканину, яка допоможе

вакуум, і тканина повинна охоплювати вакуумні отвори, щоб

переконатися, вакуумні отвори не печаткою силіконові подушки. 2-Переконайтеся, що мішок кремнію протікає. – У середньому кажучи, сумки кремнію можуть бути використані для 2 або

кобила років. Але перевірити кремнію мішок, якщо ваше ламінованого

скла мають пухирці. – Перевірте герметичність пряжку краю мішка кремнію запечатаний

прекрасно при обробці багатошарове скло з плівкою прошарок EVA. 3-Це занадто рано, щоб розмістити ламінування скла з печі,

Температура багатошарове скло і раніше дуже високий, і фільм EVA

прошарок ще тане і реагування. Коли ламіноване скло остигає,

розплавлений прошарок EVA плівка стискається, і фільм EVA прошарок не

може повністю заповнити прогалину між двома стеклами, так що бульбашки

виходять в краях. 4-Ще занадто рано, щоб зупинити пилососом. І перехресної реакції посилання плівки прошарок EVA не повністю

закінчена і стабільною. А також кремній сумка буде смоктати ж повітря

назад в сумку, які викликають бульбашки. Таким чином, взагалі кажучи,

не зупинятися пилососом, поки температура багатошарового скла нижче 45

градусів. Примітка: Завжди пам’ятайте, ви поклали провід мережі на пилосос

отвір, щоб переконатися, вакуумування не зупинити багатошарового скла

на отвір. + + Case Study: бульбашки з багатошарового скла з плівкою EVA прошарок Ми бачили ситуацію таким чином: Bubbles виходить в ламінованого скла.

І ми перевіряє всі деталі пилососом і пилососом, безумовно, не

проблема.

Але бульбашки все ще виходить в ламінованого скла. І бульбашки

регулярно і на лінії.

Нарешті ми зрозуміли, що міхур ліній право на труби опалення. Таким чином, ми знизили температуру і зробила тест. Тоді не було

бульбашок виходить, але деяка частина багатошарового скла не дуже

прозора. Отже, ми знаємо причину:

Тому що труби опалення перебувають під сумку кремнію, коли ламінування

скла, частина з ламінованого скла права на труби опалення перебувають

у високій температурі. І температура всередині духовки не перебуває в

середньому.

Пам’ятайте, що при дуже високій температурі, сополімеру і з’єднання

будуть руйнування і виробництво газу, яке може викликати бульбашок

усередині ламінованого скла.

Так що краще з вас може поговорити з EVA ламінування виробника духовки

Скло змінити печі. Якщо вам потрібна будь-яка інша інформація, будь ласка, не соромтеся

звертатися до нас. Всі права захищені ЧПУ-прошарку TECH:

【1】 Продукт CNC-Force ® EVA INERLAYER ДЛЯ АРХІТЕКТУРИ багатошарове скло

【2】 Продукт CNC-Smart ® шикарний фільм на недоторканність приватного

життя перемикаються GLASS

【】 Продукту 3 CNC-Shield ® ПВБ прошарку ДЛЯ АВТОМОБІЛЬНОГО лобового скла

Web: www.CNCnext.com

Mail: [email protected]

[email protected] /

[email protected]

Painted Glass Machine Engraved glass Carved Art Glass three dimensional effect glass

GLASS MANUFACTURER MAIN PRODUCT

======================================

Bead light

GLASS MANUFACTURER PRODUCT LIST

======================================

Painted Glass

GLASS MANUFACTURER CONTACT INFO

======================================

Address: Glass industrial base, Tengzhou City, Shandong, China

National free telephone :400 -0632-688

Tel :+86-632 -3913088 3913099

Fax :+86-632 -2658788

E-mail: [email protected]

Website: www.sdthglass.com

GLASS MANUFACTURER COMPANY PROFILE

======================================

Tengzhou TechHi Glass Co., Ltd. is a collection of glass sculpture, glass sliding door production, glass manufacture, glass materials sales, technology training and a variety of technology transfer. It is one of the large-scale private enterprises.