EVA THERMAL CUTTER tips (3)

PET GREEN TAPE FOR SAFETY GLAZING EVA PVB SGP (15)

PET GREEN TAPE FOR SAFETY GLAZING EVA PVB SGP (15)

Eva glass interlayer film for safety laminated glass, arctic snow white.jpg

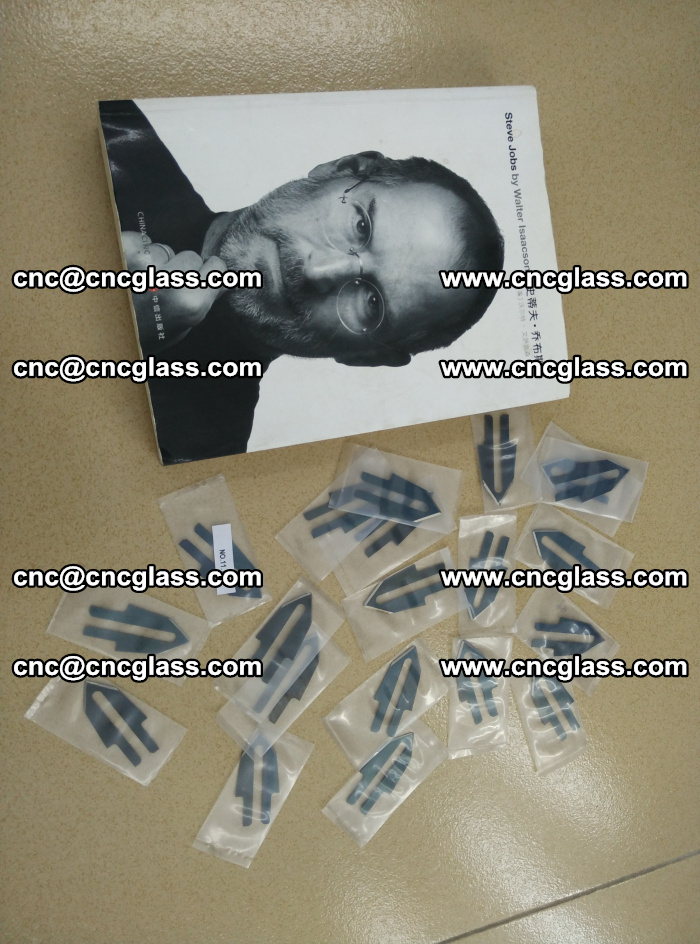

Grey clear eva glass interlayer film safety glazing samples.jpg

Blades of hot knife trimmer for eva interlayer film glass laminating

Transportation of EVA Glass Laminating Oven

2. Transportation

EVA Glass Laminating Oven Electrical cabinets, vacuum pump, storage temperature of the cooling fan:-25℃~55℃. Temperature during transportation:allow 70℃no more than 24hours.

In order to transportation,machine take apart into furnace body (include vacuum bed, vacuum bed frame),vacuum pump(diagram 3), cooling blower(diagram 3),electric cabinet, outer guide(show in the outer guide and furnace body ground connection schematic, glass loading device (hook loading construction, forklift loading construction). Make together vacuum pump, cooling blower and air purifier(also can take apart).pack the outer guide(2pieces), orbit tie bar(4pieces and assorted 16 M10 screw), cable conductor short bracket and forklift bracket.make together forklift loading construction and hook loading construction(also can take apart).pack electric cabinet single.pack furnace single.Sub-package several parts,write down the record(record into packing list),loading transportation. Re-install when reach to your factory.It should use two special ropes(can bear≥5000kg per rope)pass through furnace bottom (show forklift lifting diagram).Lifting weight of Lifting device no less than 5000kg,also forklift can instead(5tons)fork and transport(show as forklift transport diagram). on the process of Forking, hoisting should use the bandages to keep the EVA Glass Laminating Oven balance , firm to avoid occur overturning EVA Glass Laminating Oven or slide when fork and hoist. Fork movement, lifting rate should remain steady, uniform, may not be a sudden brake, so that EVA Glass Laminating Oven vibration strongly.

Hoist lifting diagram

Forklift Plug-in diagram.

The EVA Glass Laminating Oven noise is mainly from vacuum pumps, fans operation

1.3 Note on the noise

The EVA Glass Laminating Oven noise is mainly from vacuum pumps, fans operation, under the condition that EVA Glass Laminating Oven in vacuum pumps, circulating fan running at the same time, in the distance of EVA Glass Laminating Oven 1m, H1.6m test the Noise value no less than 76dB.

The level of noise emissions on Above, But not necessarily is the safe working conditions. Although the noise emission levels and exposure levels have a certain relationship, but it can not decide whether or not to be done to further prevent ion.The impact of staff exposed to actual levels of noise factors include the specific characteristics of the workshop, other noise sources, etc, for instance, The number of EVA Glass Laminating Oven and other neighboring operation.At the same time,the permissible noise exposure levels in various countries are different .in any case,This information will give the user of EVA Glass Laminating Oven a better assessment for endanger of noise generated.

Users should be based on the use of the premises environment, to identify the operator of the actual environment the noise level, determine whether it should be taken measures to prevent the noise hazard.

Safety Marks List EVA laminated glass machine safety galzing location

1.2

Safety Marks List

The following logo is affixed to the equipment dangerous place accordingly, should be regularly checked equipment on the state of security identification, signs such as damage, loss, should be replaced immediately.

1

Attention to electric shocks! On the Cabinet and the electrical Trunking

2

Attention to high-temperature! Furnace door frame

3

Mechanical hand-wound care On the Forklift loading and unloading device

4

Stumble caution On the Forklift loading and unloading device

5

Fall caution Furnace side and Appropriate location top of furnace

Under Operation, please refer to the security marking device to fully consider these safety signs and prevent the risk of the tips.